The Ideal Partner for Future Mobility

We work constantly to turn our vision into reality through core values, dedicated team working, cultivation of talent and putting passionate ideas in frame.

Taelim is an export-based automobile steering system manufacturing company specializing in mechanical tube forming and welding, input/output shaft precision machining, and intermediate shaft (I-shaft) assembly in the automobile market. Based on 30 years of cylinder tube production know-how and understanding of vehicle steering-related systems, the company has successfully transformed into a higher-level company that supplies HPS (hydraulic power steering) parts such as rack tubes and columns, as well as EPS I-shaft, Input & output shafts (electronic power steering), and ERW Pipes.

We promise to continuously provide high-quality products to our customers to realize customer satisfaction.

Our goal is to use our technology and data to help everyone live a better life.

Today, Taerim Industries is an export-oriented company that specializes in automobile parts, but our possibilities are infinite.

Like a large forest that embraces diversity, Taelim has the ability to design, manufacture, and verify on its own and organically provides sustainable solutions to meet the needs of diverse customers around the world.

Additionally, Taelim Industrial is taking the lead in changing society to protect the environment and resources by participating in the international movement to replace electricity with 100% renewable energy.

Taelim has been producing mechanical tubes for 30 years and has achieved a 10% share in the global market based on strict quality control, excellent production technology, and material management required in the automobile market.

By applying the accumulated know-how of quality, production technology, and material management to ERW pipes, we are producing the best pipes.

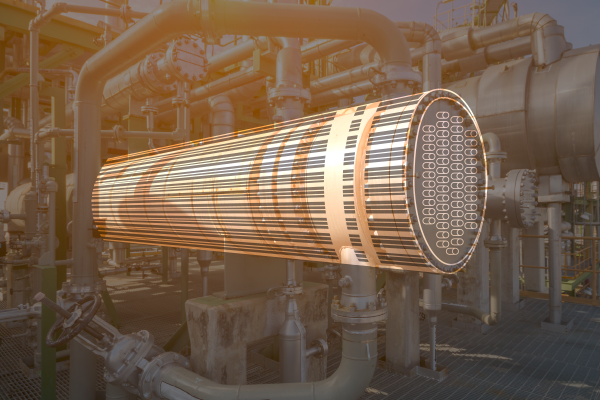

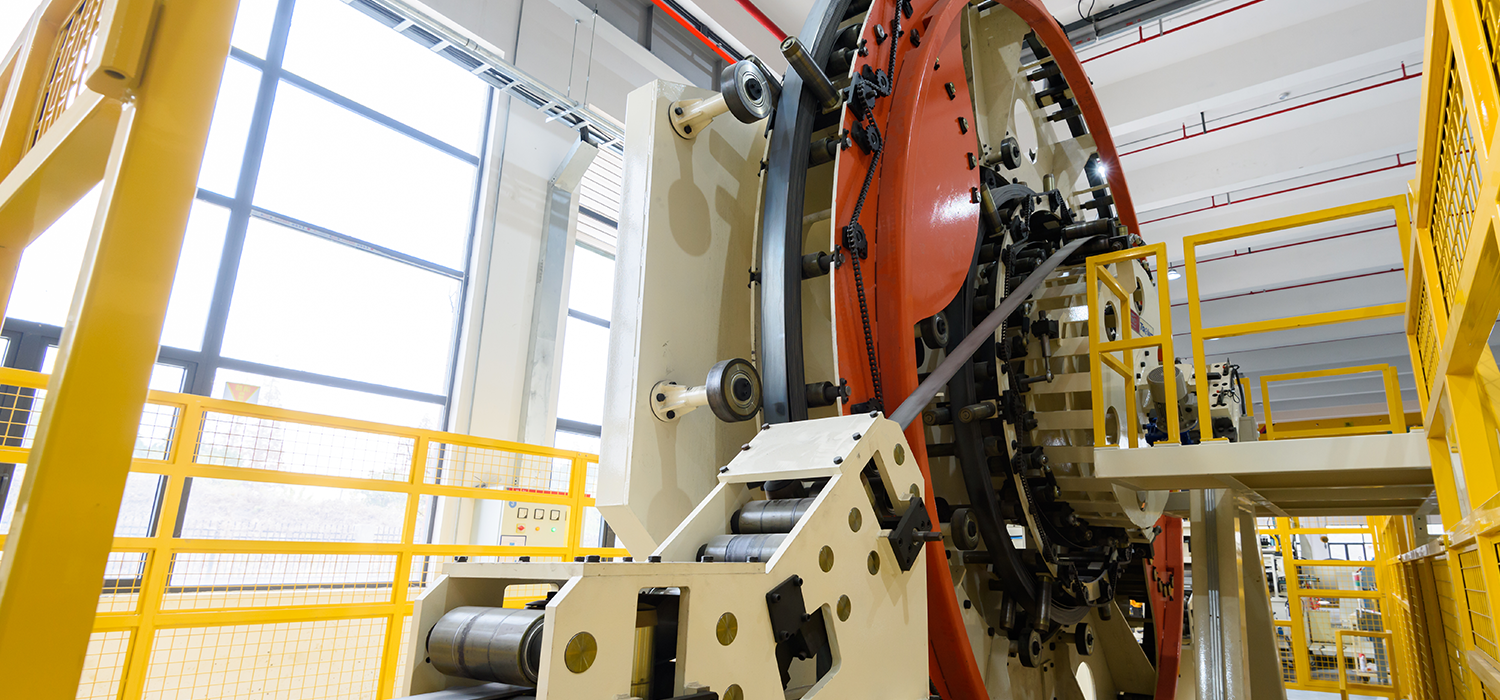

ERW Pipe is manufactured by cold forming a flat steel strip into a rounded tube and passing it through a series of forming rollers to obtain a longitudinal seam. Taelim manufactures a small diameter ERW pipe with high frequency welding based on its long experience.

| Category | Available Size | Annual Capacity | >Major Products | |

|---|---|---|---|---|

| External Diameter | Thickness | |||

| Tube Mill 1 (unit 1) | ø19.1 ~ ø76.3 | 1.0 ~ 4.0 | 18,000 | Boiler tube & Heat exchanger |

| Tube Mill 2 (unit 2) | ø25.4 ~ ø76.3 | 3.0 ~ 7.0 | 24,000 | Automobile & Contruction equipment |

| Tube Mill 3 (unit 3) | ø21.7 ~ ø63 | 2.0 ~ 8.0 | 24,000 | High strength and extremely thick wall by using high-tensile grade steel |

| Tube Standard | DIN(EN10305), API, ASTM, JIS, BS, KS |

|---|---|

| Steel Grade | E235, E355, 22MnB5, 26MnB5, 34MnB5, 37Mn5 |

| Type | Varying wall thickness ERW pipes, Square pipes |

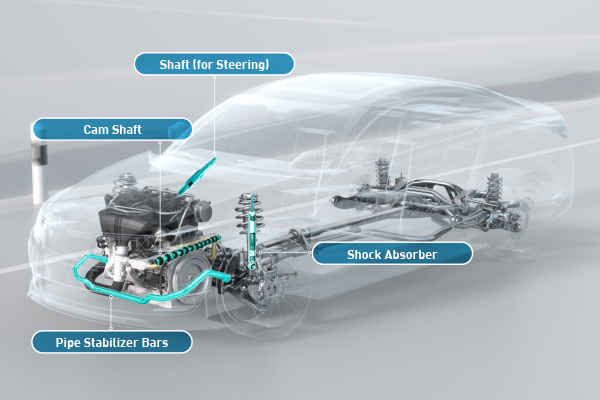

| Application | Stabilizer, Cam shaft, Steering shaft, Piston rod, Propeller shaft, Drive shaft, Hydraulic cylinder tube, Boiler tube, Heat exchanger, Crane |

Stabilizer, Cam Shaft, Steering Shaft

Construction Heavy Equipment, Excavator, Crane

Heat Exchanger

Segway, E-bike, Electric Kick Scooter, Electric Mobility Cart, Wheelchair

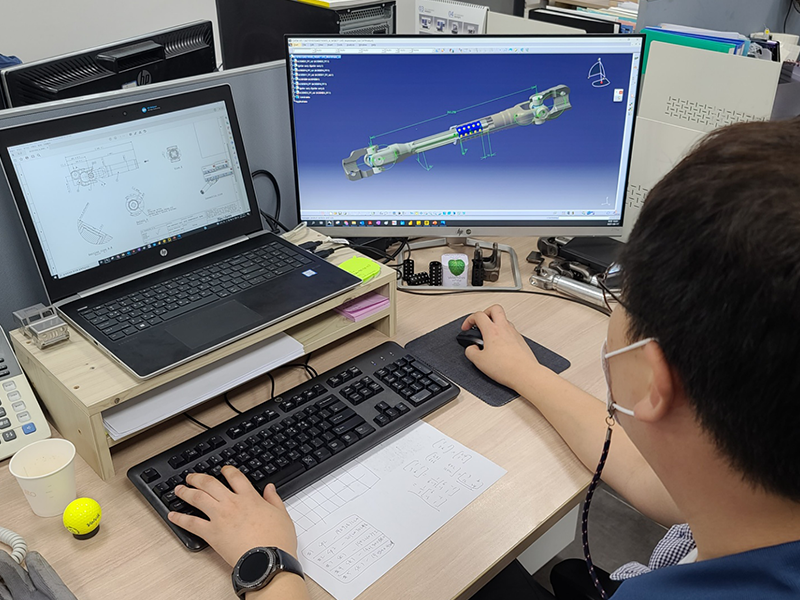

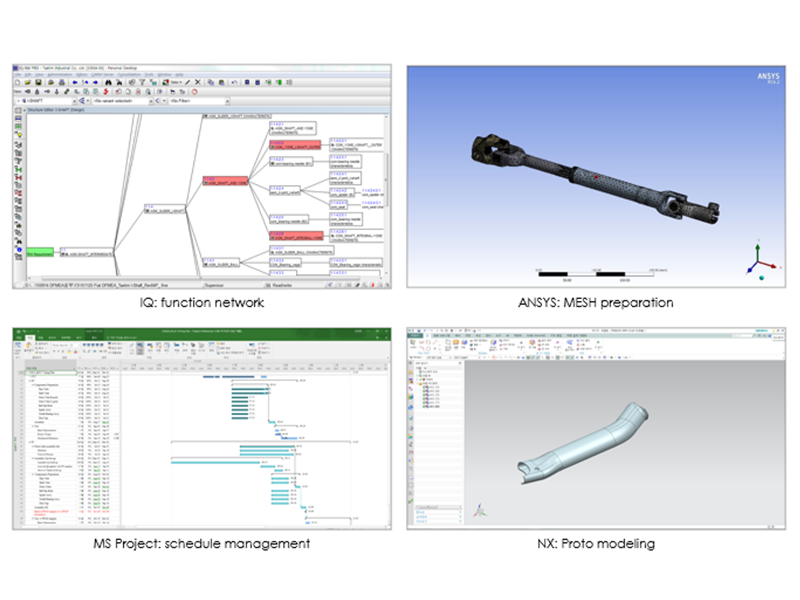

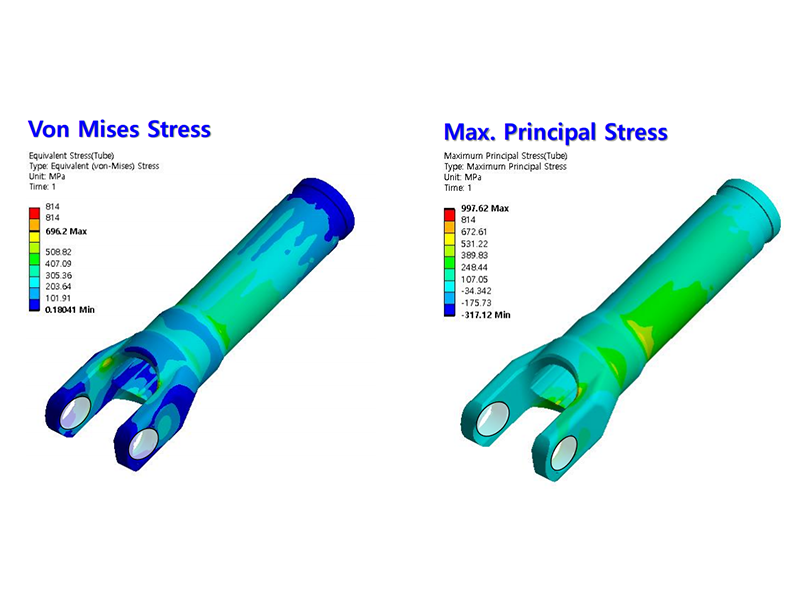

Taerim Industries has its own design/analysis capabilities as well as manufacturing and assembling capabilities, and operates an IQ-FMEA system to meet customer expectations for the design. We utilize various software such as IQ and ANSYS to analyze potential malfunctions and impacts of products, and realize customer needs with our own design technology that considers specific characteristics of each part of the product.

If you can't find an answer to your questions, please don't hesitate to contact us. We will reply as soon as possible.